Keeping Cargo Cool

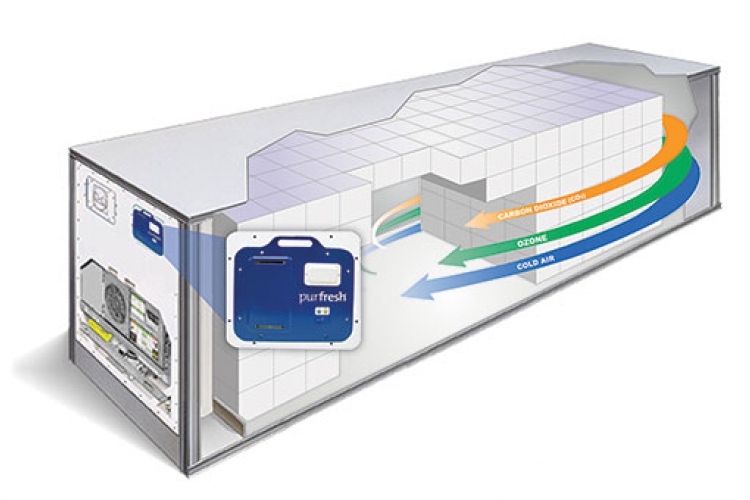

The global network that manages your international refrigerated cargo transport is complex. The transport process for a piece of fruit, or high value cargos such as pharmaceuticals, move from a loading warehouse in one country and arrive at an unloading warehouse in another country, while involving many different modes of transportation. When these cargos require specific maintained temperatures, many shippers and exporters utilize 40-foot-long, ocean going refrigerated containers, most commonly referred to as “reefers” or reefer containers.